General questions product use

Application guidelines for the product BIRKOSIT Dichtungskitt®

Pressure/temperature conditions in the turbines [individual pressure zones]

- Defined by type of turbine

- Generally, the critical point for pressure is the turbine inlet (~70 bar)

- Generally, the critical point for temperature is the turbine inlet (~500 Grad)

- Special case, turbine type “H” – ‘pushed up’: turbine inlet is critical point (~120 bar/600 degrees) → e.g. HNG 4056

Relevant working steps

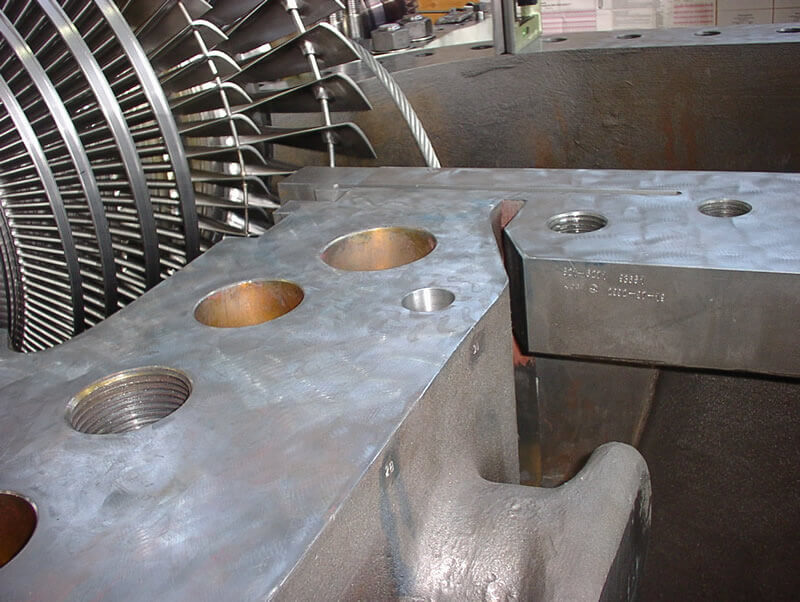

1) Internal sealing surfaces (joints) – guide blade carriers [BIRKOSIT Dichtungskitt® is applied with a brush] → consumption on average 2 to 3 tins

Individual steps in stage 3

- Remove the hard top layer [protective layer] from the tin with a spatula.

- Mix in linseed oil until a proportion of 1/10 is reached.

- Apply to the joint surfaces with a brush.

- Spread thinly.

- The joint surfaces must be dry and machined [and rubbed down] to the required precision.

- Close the pressure stage casing halves.

- BIRKOSIT Dichtungskitt® WILL FILL ANY SURFACE IRREGULARITIES.

Important note on work step 2

- Preparing the surfaces using engineering blue

- Apply blue to sealing surface of one casing half

- Match up second half (with blue print) exactly [work unevenness of first half into second]

Important note on work step 3

The joint surfaces are milled with high precision [Ra = 0.8 to 1.2 μm].

In order to provide the BIRKOSIT Dichtungskitt® with an optimum adhesion surface, the joint surfaces are briefly ground using a finishing sander with 60-80 grade disc [where manufactured with sufficient precision not necessary].

Reconditioning intervals

– between 3 and 10 years [or calculated in operating hours]

Product use by end-customers

– between 3 and 10 years

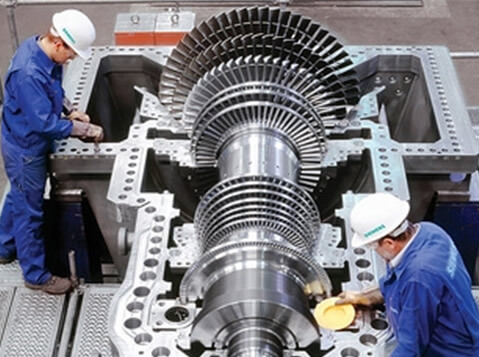

Example SIEMENS Steam Turbine SST-6000

The SST-6000 features a barrel-type high-pressure (H) cylinder, an intermediate-pressure (I) cylinder and up to 3 double flow low-pressure (L) cylinders for 50 and 60 Hz.

It is typically operated in conventional steam power plants and enables a power output up to 1200 MW.

Output Range

for Conventional Steam Applications

• Up to 1200 MW Main Steam

Temperature:

• Typically 600° C / 1112° F

Pressure:

• Up to 280 bar/ 4061 psi

Reheat Steam Temperature:

• Typically 610° C / 1130° F

Exhaust Areas

• 50 Hz: 5 m² to 16 m²

• 27.5 inches to 56 inches*

• 60 Hz: 3.5 m² to 11.1 m²

• 22.9 inches to 47 inches** Last blade

Storage Life of BIRKOSIT Dichtungskitt®

Unopened tins

When correctly stored in the original packing, we guarantee a storage life of 5 years.

Tins in circulation

Where tins are properly closed after partial use, we guarantee a storage life of 3 years.

Service life

When used in accordance with instructions and with regular servicing as required for steam and gas turbines, we guarantee a service life for use on machined sealing surfaces (butt joints), of 10 years.

For the high-pressure (H) turbines, we guarantee that the product will withstand hot steam, hot air, hot and cold water, light fuel oils, lubricants, mineral oil and natural gas at temperatures up to 900 °C and pressures up to 250 bar.

Pressure resistance

The excellent adhesion on sealing surfaces and butt joints guarantees a perfect seal up to 250 bar.

The pressure resistance for flanges without sealing rings is up to 450 bar, and even up to 550 bar for screw joints.

Indication of storage life

From 1 Jul 2002, the following additional information will be printed on the label:

– Filling date:

– Unopened, useable until: 5 years

– Opened on:

Storage life after opening: 3 years

®Copyright A.I. Schulze 2019

Source: Siemens AG 2010